Proper air ventilation systems equipped with the right filters are crucial in operating rooms to minimize the risk of hospital-acquired infections (HAIs). Read on to learn why and how.

A clean environment is vital for every healthcare facility to prevent and control infections. One major way to ensure this is by managing indoor air quality, which helps in reducing the spread of airborne diseases that can threaten the well-being of patients, staff and visitors.

When people infected with a virus sneeze or cough, they release microbes into the air, which can lead to hospital-acquired infections (HAIs). Shockingly, over 100,000 people die from HAIs every year.

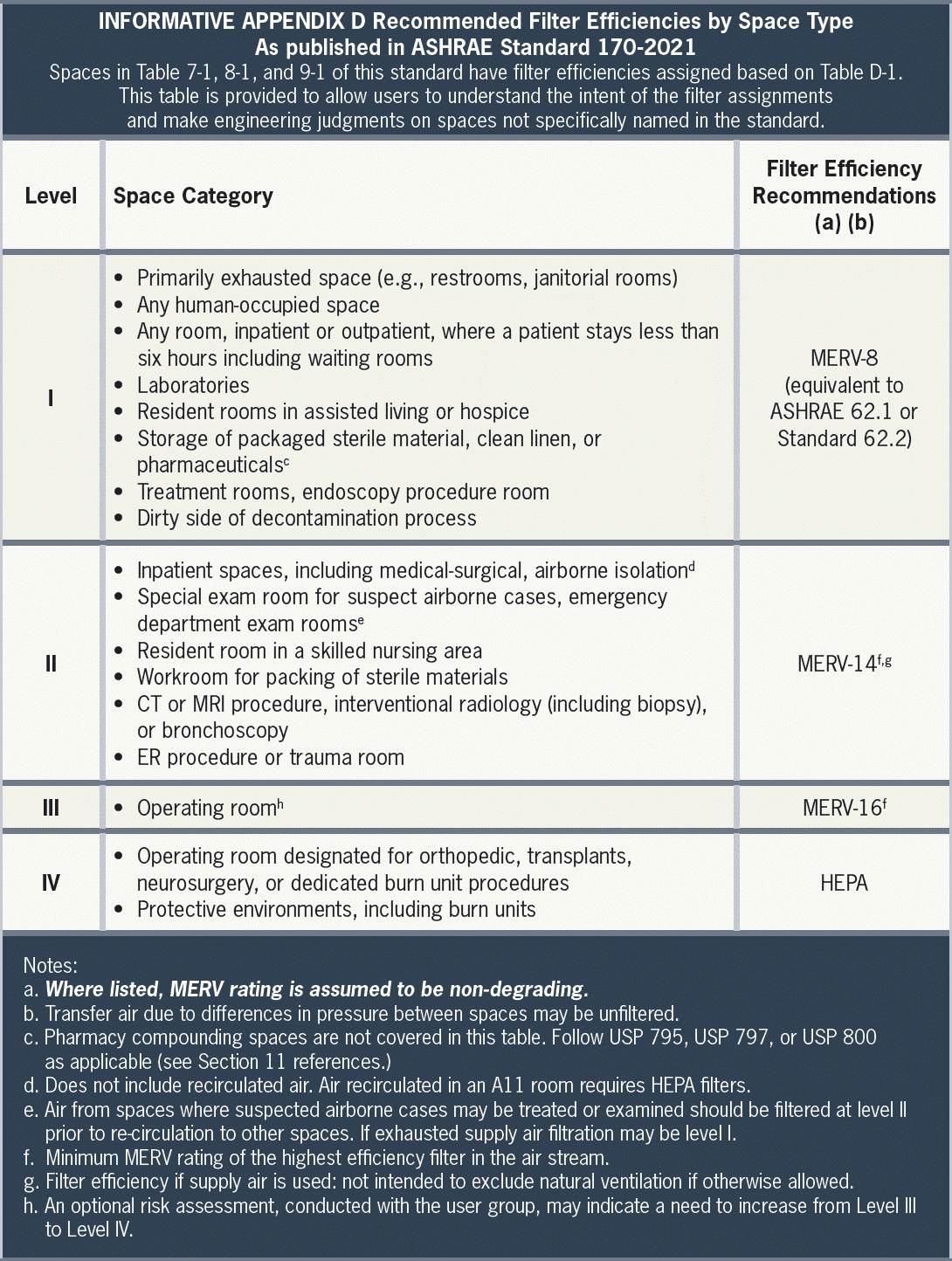

The Centers for Disease Control (CDC) has air quality guidelines for healthcare buildings. ASHRAE has a design standard (Standard 170) devoted solely to ventilation in healthcare facilities.

Different spaces, like patient rooms and pharmacies, have varied requirements. Operating rooms intended for high-risk surgeries have the highest standard of air quality because during these types of surgeries, patients’ organs are often exposed, making them more prone to infections.

Apart from viruses, other pollutants can compromise the sterility of surgical areas:

- Leaked anesthetic gases during procedures

- Dust and smoke particles from medical tools

- Infectious aerosols released during surgeries

- Bacteria from skin scales shed by people in the operating room

Ensuring top-notch air quality is more than just a protocol – it’s a lifeline for patients.

How Airborne Contaminants Cause Surgical Site Infections

Surgical site infections (SSIs) can occur due to airborne contaminants. These post-surgery infections not only delay a patient’s recovery but can also lead to severe conditions. SSIs account for a large chunk of HAIs, resulting in longer hospital stays, unexpected readmissions, increased costs and negative patient outcomes. Consequently, they can lower a hospital’s quality rating. Two to five percent of patients suffer from SSIs after a surgical procedure.

The link between SSIs and airborne bacteria in operating rooms is clear: the more bacteria in the air, the higher the risk of infection. Surprisingly, 80% of bacteria found in post-surgery wounds originate from the operating room’s air. Factors affecting contamination levels include the size of the surgical room, the equipment used, the number of staff, and the length of the surgery.

Air Ventilation Reduces SSIs

Proper air filtration can lower the chances of SSIs and HAIs, by minimizing nosocomial contamination. It’s worth noting that standard HVAC systems aren’t sufficient to purify the air in operating rooms.

Research from the National Library of Medicine highlights the crucial role of ventilation systems in operating rooms. These systems help control airborne impurities, thereby reducing SSI risks. By effectively capturing contaminants near sterile areas, like the operating table, and reducing their reintroduction from non-sterile zones, we can see a decrease in SSIs. A well-ventilated room can lead to fewer infections in surgeries, ensuring improved patient outcomes.

Appropriate Air Filtering Rates

The International Society for Infectious Diseases recommends that operating rooms should be virtually free of particles larger than 0.5 µm when unoccupied. In addition, the ANSI/ASHRAE Standard 170-2017 provides guidelines for patient care area air filtration, including operating rooms.

ASHRAE’s guidelines define Minimum Efficiency Reporting Values (MERV) for filters used in air systems. These filters are designed to capture a variety of particles, including harmful pathogens and common dust. When coupled with molecular filters and installed in special exhaust systems and fume hoods, these filters can trap gases, vapors and particulates.

To understand how effective a filter is, we look at its particle removal efficiency. MERV ratings are listed in the table below from page 45 of ANSI/ASHRAE Standard 52.2-2017. It ranks filters from 1 to 16 based on their efficiency. A rating of 16 indicates the highest efficiency in trapping the tiniest of particles.

MERV Ratings for Filtering Applications

| MERV Rating | Average Particle Size Efficiency in Microns | Controlled Contaminants | Applications | Typical Air Filter |

| 1-4 | Greater than 10.0 µm | Pollen

Spanish moss Dust mites Sanding dust Spray paint dust Textile fibers Carpet fiber |

Minimum filtration, Residential, Window air conditioners | Throwaway: Disposable fiberglass or synthetic panel filters

Washable: Aluminum mesh, latex-coated animal hair, or foam rubber panel filters Electrostatic: Self-charging (passive) woven polycarbonate panel filter |

| 5 – 8 | 3.0 to 10 µm | Mold Spores

Hair spray Fabric protector Dusting aids Cement dust Pudding mix Snuff Powdered milk |

Commercial buildings, Better residential, Industrial workplaces, Paint booth inlet air | Pleated Filters: Disposable, extended surface, 25 to 125 mm (1 to 5 in.) thick with cotton-polyester blend media, cardboard frame.

Cartridge Filters: Graded density viscous coated cube or pocket filters, synthetic media. Throwaway: Disposable synthetic media panel filters. |

| 9 – 12 | 1.0 to 3.0 µm | Legionella Humidifier dust

Lead dust Milled flour Coal dust Auto emissions Nebulizer drops Welding fumes |

Superior residential, Better commercial buildings, Hospital laboratories | Bag Filters: Nonsupported (flexible) microfine fiberglass or synthetic media. 300 to 900 mm (12 to 36 in.) deep, 6 to 12 pockets.

Box Filters: Rigid-style cartridge filters 150 to 300 mm (6 to 12 in.) deep may use lofted (air-laid) or paper (wet-laid) media. |

| 13 – 16 | 0.3 – 1.0 µm | All bacteria

Droplet nuclei (sneeze) Cooking oil Most smoke and insecticide dust Most face powder Most paint pigments |

Hospital inpatient care General surgery | Bag Filters: Nonsupported (flexible) microfine fiberglass or synthetic media. 300 to 900 mm (12 to 36 in.) deep, 6 to 12 pockets.

Box Filters: Rigid-style cartridge filters 150 to 300 mm (6 to 12 in.) deep may use lofted (air-laid) or paper (wet- laid) media. |

Best Filter or Ventilation System Choices

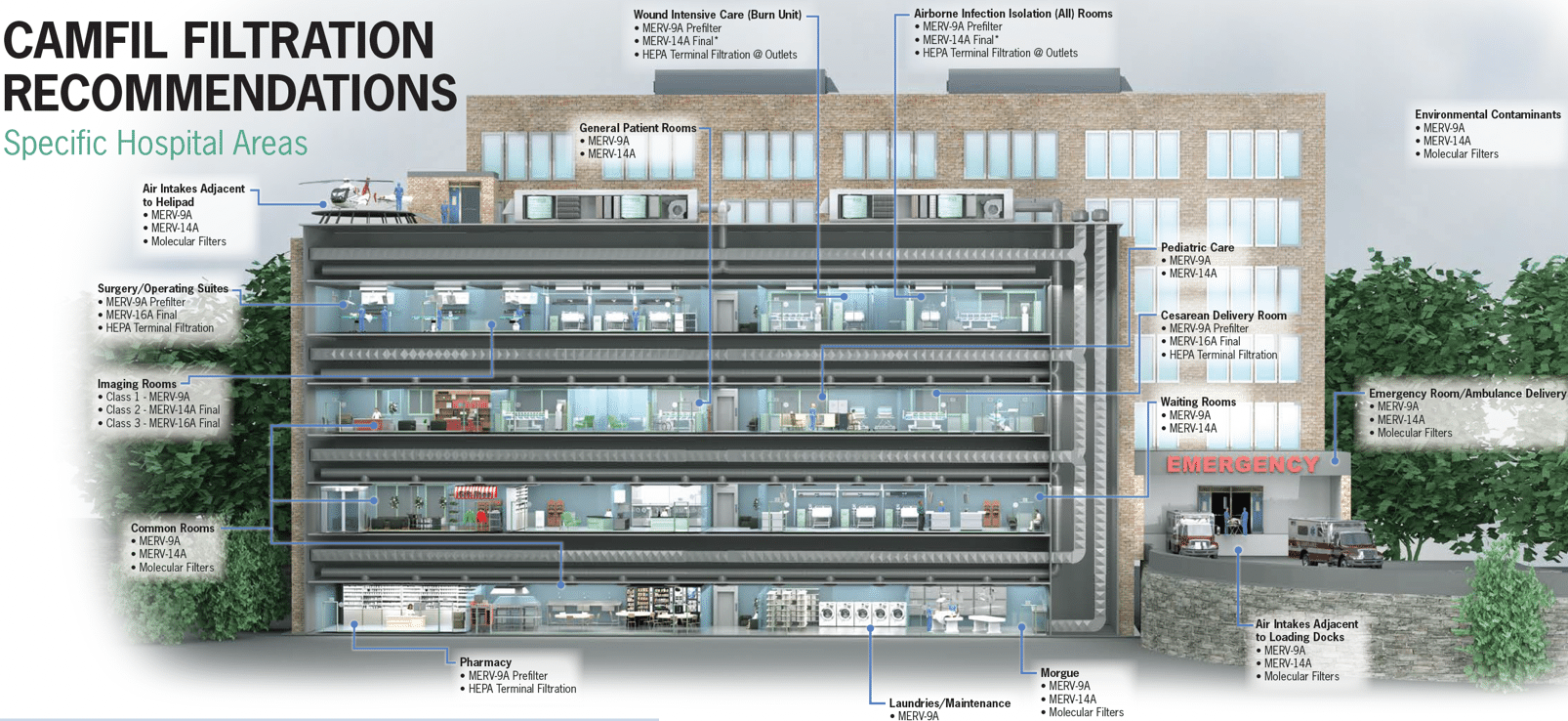

For HVAC systems in residential, commercial and general hospital settings, filters rated up to MERV 14 are recommended. For more critical areas of a hospital including certain surgical operating rooms, airborne infection isolation rooms, burn units and protective environment rooms, HEPA filters with a minimum tested efficiency of 99.97% @ 0.3-microns are required because they effectively capture finer particles.

ASHRAE has revised its standards, raising the filtration requirement from MERV 14 to MERV 16 for specific surgical areas including:

- Operating rooms

- Outpatient surgical facility operations rooms

- Inpatient and outpatient Class 3 imaging rooms

- Operating/surgical cystoscopy rooms

- Cesarean delivery rooms

In these spaces, HEPA filters are often preferred due to their higher efficiency. Installing HEPA filters ensures that hospitals achieve the needed filtration level for any operating room.

The table below outlines the intent of the ASHRAE 170-2021 committee when determining filtration efficiency recommendations for space categories in healthcare facilities.

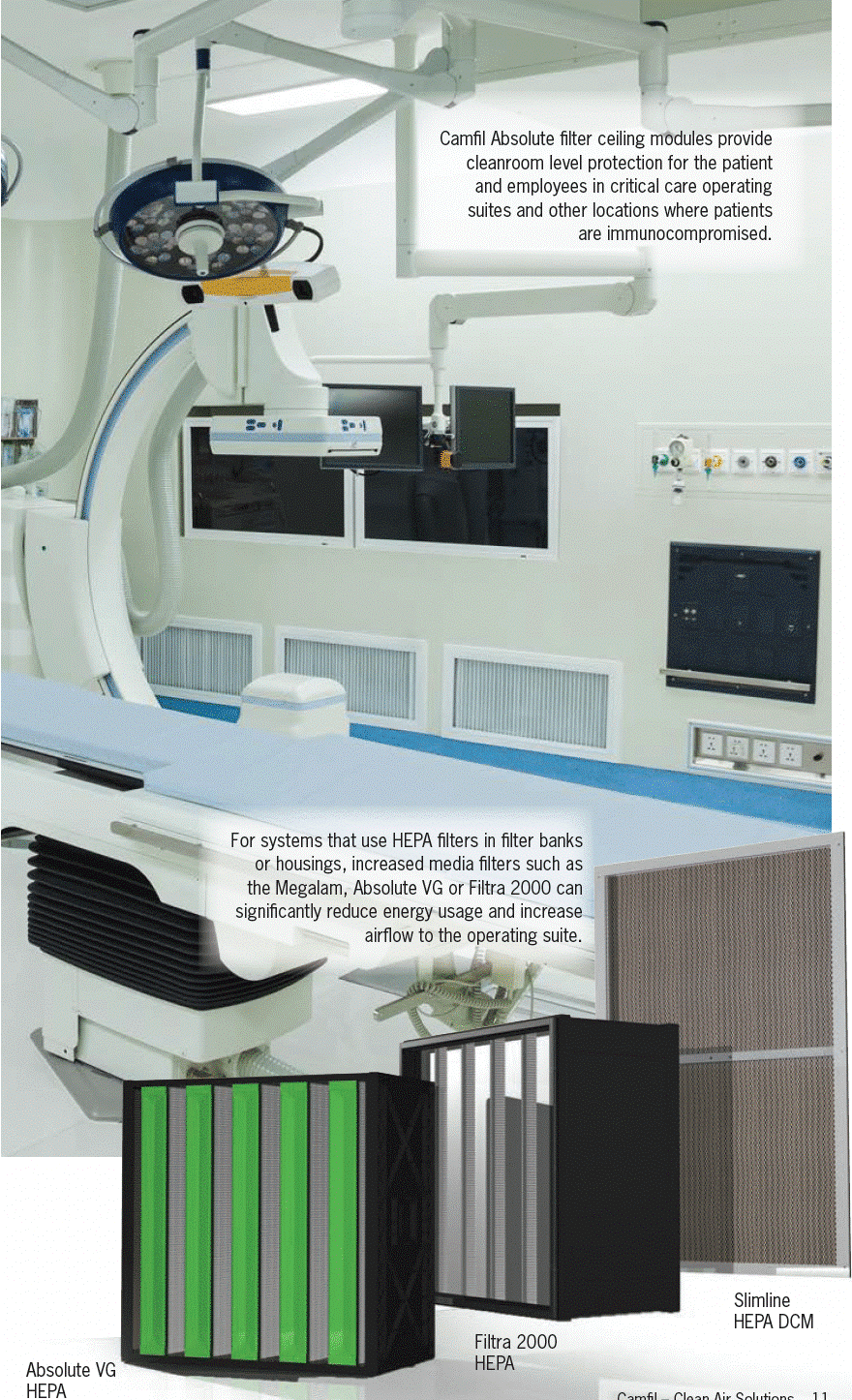

It’s important to note that HEPA filters typically don’t function independently in an operating room’s ventilation system. A comprehensive overview below explains how various filters can collaborate or tackle specific challenges in surgical environments.

It’s important to note that HEPA filters typically don’t function independently in an operating room’s ventilation system. A comprehensive overview below explains how various filters can collaborate or tackle specific challenges in surgical environments.

Filter Overview

HEPA Filters

The common minimum definition of high-efficiency particulate air (HEPA) filters most commonly available in North America are those filters tested to remove 99.97% of tiny airborne particles, down to 0.3 µm in size. They play a crucial role in:

- Filtering out pathogens and contaminants in operating rooms

- Ensuring clean air in patient wards, nurseries, and treatment rooms

- Venting air from fume hoods and safety cabinets, especially those handling infectious or radioactive substances.

These filters come in diverse designs and materials, such as aluminum, plastic, various steels, wood and particle board. Notably, Camfil provides specialized HEPA filters: panel-style for terminal filtration and box-style for make-up air or recirculation units, enhancing the protection of primary HEPA filters.

In large-scale installations, air that flows through the HVAC also travels through the HEPA unit.

General Ventilation Bag Filters

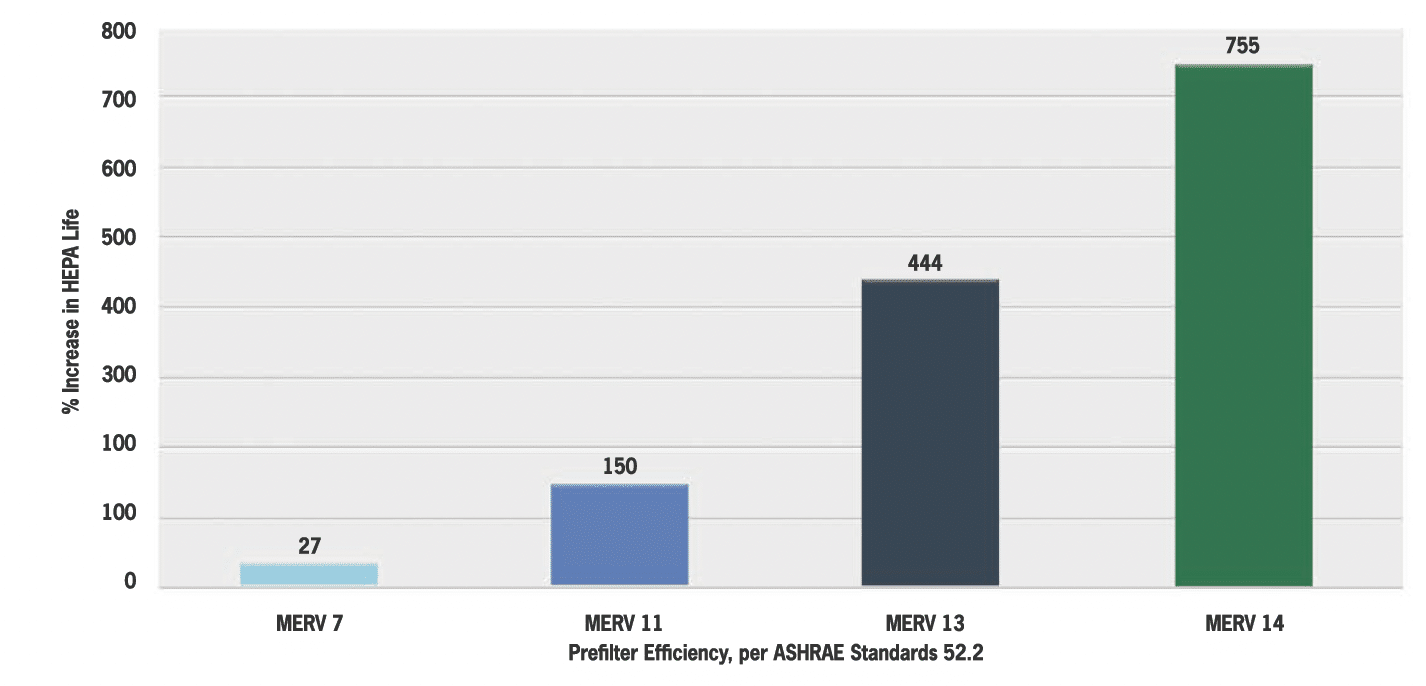

Bag filters often serve as prefilters in air handling units with HEPA filters located downstream. These prefilters target larger particles like dust before they reach the primary HEPA filter. By doing so, they extend the lifespan of the costlier, high-efficiency final filters. Camfil offers the HI-FLO ES multi-pocket, high-efficiency bag filter, as a prefilter for cleanroom process applications such as operating rooms. These filters come in various MERV ratings and configurations.

The chart below shows how prefilters increase HEPA filtration life. When the life cycle cost of the HEPA is considered, MERV-13 or MERV-14 ASHRAE prefiltration is the norm.

Molecular Air Filters

Molecular Air Filters

Often referred to as chemical or gas-phase filters, molecular air filters remove gases, vapors and molecules from the air via a specific process known as molecular filtration. These filters are remarkably effective, trapping airborne chemical molecules that are 1,000 to 10,000 times tinier than those caught by conventional HEPA or ultra-low particle filters.

Hospitals use these filters to eliminate odors from substances like formaldehyde and gases such as hydrogen peroxide used for sterilization.

In one hospital application, a Camfil molecular air filter was used to remove fumes and particles generated from vehicle combustion s that were polluting operating rooms. The air circulated from the exhaust vented directly into the operating room. Even with adequate filtration, noxious gases were still infiltrating the hospital via the building’s HVAC system. To address this, the molecular filter, equipped with activated carbon, was integrated into the system.

The challenge was finding room within the HVAC system to accommodate a filter equipped with carbon media. Camfil’s solution was its 2-in-1 City-Flo Air Filter. This innovative filter combines media to capture particles and molecules, and it was strategically placed within air handling units across various hospital buildings. As a result, issues related to dust, fumes, and unpleasant odors were effectively addressed.

Ultra-Low Particulate Air (ULPA) Filters

ULPA filters are a step above HEPA filters in terms of air purification. They capture an impressive 99.999% of particles as small as 0.1 µm, ensuring unparalleled air cleanliness. These filters are especially efficient in removing harmful elements, including bacteria and viruses. Some healthcare facilities may specify ULPA filters for critical areas of the operating room or staged after prefilters or HEPA filters to remove the smallest particles.

The Role of Filters in Curbing HAIs

In U.S. hospitals, roughly one out of every 25 patients contracts an infection related to their hospital care, with some of these infections originating from surgical procedures in the operating room. Proper air ventilation systems equipped with the right filters can play a pivotal role in preventing these infections.

HEPA filters are generally recommended for critical surgical settings. However, to optimize air cleanliness, these can be combined with high-efficiency MERV filters, molecular air filters, or ultra-low particulate air filters. This combination not only captures minute particles, gases, and odors beyond the capability of HEPA filters alone but also prolongs the lifespan of the filters.

Different hospital zones have distinct filtration needs. While surgical or operating rooms benefit most from HEPA filters, spaces like common rooms, maintenance zones and waiting areas can rely on filters with lower MERV ratings.

By choosing the right filter or combination of filters, healthcare facilities can greatly improve indoor air quality. This not only aids in infection control but also fosters a safer and more conducive environment for patient recovery.

By choosing the right filter or combination of filters, healthcare facilities can greatly improve indoor air quality. This not only aids in infection control but also fosters a safer and more conducive environment for patient recovery.

The post Improving Air Quality in Operating Rooms Reduces Risk of Infections appeared first on Air Filters for Clean Air.

from Air Filters for Clean Air